Views: 10 Author: Jiayuan Publish Time: 2023-10-31 Origin: Jiayuan

Triacetin (GTA) application in the field of plastics

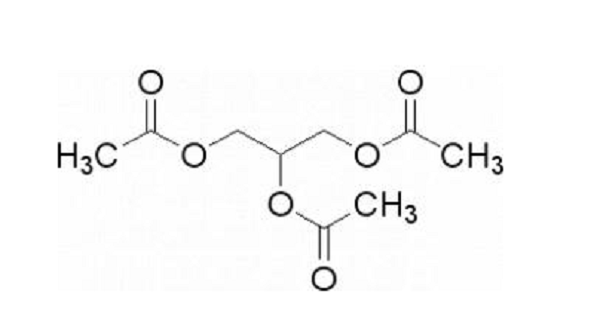

Triacetin, GTA for short, CAS NO. 102-76-1 is a commonly used plastic additive and has a wide range of applications in the plastics industry. GTA has good solubility and plasticity properties, which can improve the processability, softness and ductility of plastics, making it more suitable for the production of various plastic products.

First of all, GTA is widely used in polyvinyl chloride (PVC) products. Because PVC itself is more brittle and hard, it is easy to crack and fracture, affecting its service life and safety. GTA can increase the softness and ductility of PVC, making it more durable and impact resistant. At the same time, GTA can also improve the transparency and gloss of PVC, making PVC products more ornamental and decorative.

Secondly, GTA also has a certain application in polypropylene (PP) products. PP is a kind of plastic with excellent properties, but its hardness is high, toughness is poor, and it is easy to crack and fracture. The addition of GTA can improve the softness and ductility of PP, increase its toughness and impact resistance, and improve the mechanical strength and wear resistance of the product. At the same time, GTA can also improve the thermal stability and weather resistance of PP, and extend the service life of the product.

In addition, the application of GTA in polyurethane (PU) products is also very important. PU is a kind of polymer material with excellent properties, which is often used to make foam, coating, adhesive and other products. The addition of GTA can improve the softness, ductility and elasticity of PU products, and improve its processability and physical properties. At the same time, GTA can also reduce the hygroscopicity and water absorption rate of PU products,improve its water resistance and weather resistance, and extend the service life of products.

Finally, GTA is also widely used in other plastic products, such as polyethylene (PE), polyvinylidene chloride (PVDC), polystyrene (PS) and so on. By adjusting the amount of GTA and the proportion of formula, the performance and characteristics of plastics can be improved according to different needs to meet the application needs of different industries and fields.

In a word, triacetin has a wide range of applications in the plastics industry. Its good solubility and plasticity can make plastic products more processable, soft and malleable, improve the quality and performance of the product. With the development of science and technology and the continuous improvement of people's performance requirements for plastic products, the application prospect of GTA in the plastic industry will be broader.

Welcome Join 24th China International Agrochemical & Crop Protection Exhibition (13-15 March, 2024) Our Booth No. 81N32

Diethylene glycol ethyl ether acetate(DCAC) is mainly used as a bonding agent for latex paint. Due to its excellent solubility and slow evaporation rate, it is an ideal solvent in the production of slow-drying nitrocellulose paint, natural paint or spray painting processes.

Ethylene glycol butyl ether acetate is a kind of high boiling point polyfunctional binary alcohol ether ester solvent, which can be used as an assistant coalescent for latex paint. It has excellent solubility for a variety of paints. So it can be used as ink solvent and baking paint, especially suit

The central management team promotes learning internally

The party secretary and his delegation came to guide

Choosing a high boiling point solvent manufacturer is an important decision related to product quality and supply stability. Here are some tips to help you choose the right manufacturer.

Evaluation of the application effect of propylene glycol diacetate in coating additives

Propylene Glycol Diacetate (PGDA) is applied in production of polymer materials

Our Business Partners From Many Regions and Countries All Around World

PGDA is a high-boiling solvent. It has the advantages of low taste and low toxicity, strong solubility, good hydrophobicity and high diester content (≥99.5%). Because the diester produced by using propylene glycol instead of ethylene glycol has very low toxicity, it can be called a super environment